In previous command centers, the viewing area used LED video walls with substantial bezels between the individual display modules, which caused visual separation that could detract from the situational awareness of the operators. Contemporary solutions overcome this obstacle with newer technology such as the Chip-On-Board (COB) packaging, where the LED chips are directly disposed on the substrate. No normal wire bonding is necessary, allowing total integration, rather than simply walled-off attachment. Bezel less screens for cockpit operations enables minimal distraction for emergency response teams that require clear line of sight to surveillance grids or weather.

Seamless Visual Experience Unlike any other display solution, the MicroLED technology system is aligned without seams at the micro-level and is considered an self-emissive display in the inorganic material. This results in pixel gradients of less than 0.6mm, and thus even cinema-grade resolutions of over 8K in control room walls can easily be realised. MicroLED Unlike Quantum Dot The big difference comes to light with 5,000 nit brightness: extreme intensity, no burn-in risk from images run 24/7. Advanced surface mounting maintains the lumen uniformity of the image across viewing angles, so there is no color shift on the screen when the team is interacting. Military installations and nuclear plants in particular, have the most to gain from the fail-safe redundancy offered by micro-panels' failure rate of less than.0001% of a single pixel.

Modern 0mm bezel LED display systems achieve visual continuity through three interconnected technical pillars, combining precision engineering with intelligent software protocols for mission-critical applications.

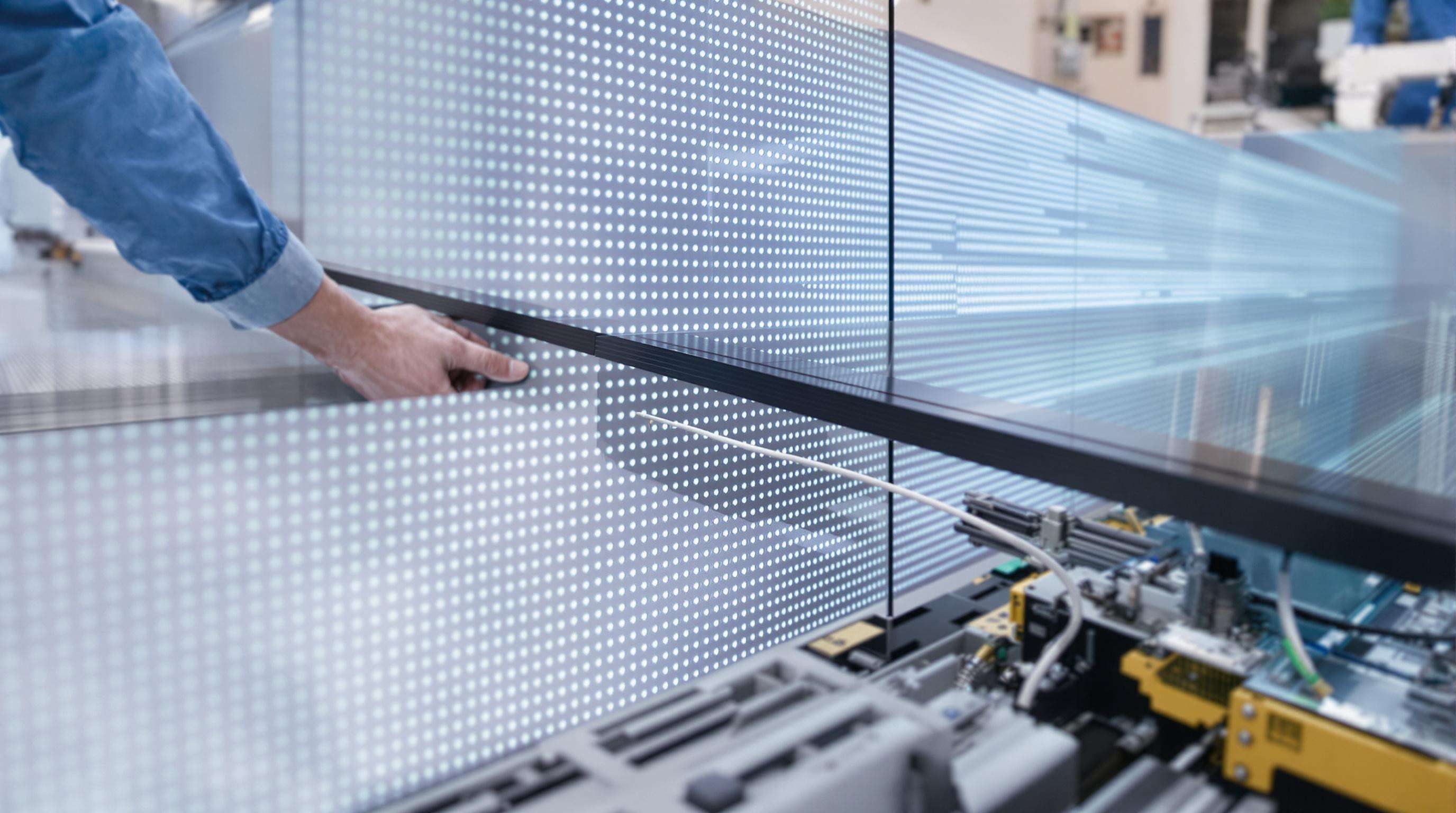

The basis is chip-on-board (COB) modules with a minimum size of more than 3cm² mounted on an extremely thin polyimide. These micro-panels are interlocked using electromagnetic connectors and self-align when assembled to within a gap tolerance of less than 0.1 mm. Enhanced cooling channels machined into the substrate preserve the thermal robustness of the sub-assembly on coated stages, even under prolonged use conditions. The COB-based tiling saves 18% power when compared with SMD counterparts, and increases impact resistance likewise.

During the calibration process, post installation machine vision is used to map the color profile of every panel across 256 levels of brightness. Real-time compensation methods compensate LED aging differences to keep delta-E color accuracy below 1.5 for the whole display wall. A system of sensors saves the day, triggering a self-correction loop to adjust pixel output every 15 milliseconds, thus eliminating ambient light to ensure tactical maps and live sensor feeds are indistinguishable from any perspective.

Control center management solutions natively integrate with SCADA and IoT device networks. Operators can revise screen areas on the fly with drag-and-drop user interfaces, and they can also overlay predictive analytics models on top of live surveillance feeds. Touchless gesture commands make it easy to scale key data visualizations up while keeping other workflows uninterrupted. API-centric architectures enable 3rd party AI modules to directly modify display parameters resulting in smart interfaces that dynamically rearrange content in response to variabilities in threat severity and operational phases.

With bezel-free LED displays, there are no visual barriers between panels, allowing for the seamless viewing of incoming real-time data streams. This will enable response teams to monitor live events – for example, weather or crowd behaviour – without stuttering perceptual gaps that can hold up analysis. Command centers that use this tech have seen a 27% (that's right!) increase in the speed of incident response due to the enhanced spatial understanding of unfolding situations. Wide viewing angles ensure perfect image clarity for all operators, essential when coordinating multi-agency responses.

These displays feature 100% sRGB color accuracy and 4K resolution for each panel, which ensures that complex data set images are rendered without compression. Banks with bezel-free walls are 19% more accurate at reading market trends than those with a bog-standard wall. One of my favorite things about this is the lack of bezels Screens won't cut up things (like a chart axis may not start on an even number, or a heatmap may be cut off) which keeps the geometry valid for the predictive models. All this is important when tracing AI-driven analytics over live infrastructure maps or resource allocation matrices.

Counterintuitive increase of LED wall lifetime of bezel-free assemblies as a consequence of continuous operation. The solid-state design has 24/7 workloads and <0.1% annual failure rates, while traditional displays have 3-5% performance failure on an annual basis. Novel sub-systems for advanced thermal management more efficiently remove heat from the contiguous panel array to mitigate localized component stress.

Contemporary companies now integrate bezel-free LED displays with a smart (BMS) that connects all environmental controls, security protocols and data visualization interfaces into one integrated network. This convergence allows for automatic lighting, climate and content display adjustments according to occupancy or emergency situations – and even responds in real-time, 30% more power efficiently. Video walls can dynamically superimpose egress routes over surveillance feeds once a crisis occurs, alerting the team responsible for the facilities and turning the display into an active response center.

Overall Summary Scalability is the cornerstone of successful LED network deployments, and modular micro-panel architectures provide corporations the ability to increase display real estate over time without the need to rip out and replace infrastructure. Financial rewards also arise from predictable lifecycle management, having systems that scale as needs grow – add dashboard panels for new departments, expand war rooms for mergers. Consistent calibration procedures ensure a consistent visual appearance of spliced displays through the life of the video wall and the original content. Cloud-based control systems through which geographically diverse installations may be managed remotely and where upgrades and troubleshooting are centralized. This future-proof solution decreases total cost of ownership (TCO) by 40% versus fixed solutions and preserves the ability to adapt to changing spatial needs.

Contemporary control rooms are depending more and more on predictive maintenance models that use the power of AI to predict LED display failure. Such systems monitor temperature change, pixel degradation, power consumption and other operational conditions in real time and predict 92 percent of wearing out of components. By combining COB LED displays’ modular design with machine learning, plants minimize unscheduled downtime by 37 percent and extend display life beyond industry-average limits.

For augmented reality (AR) workstreams, such as realtime logistics data, 3D threat modelling and collaborative design simulations, next-gen LED walls double as spatial canvases, overlaying them onto the physical world. The result of this convergence is to eliminate any delays caused by context switching in responding to a crisis and allow operators to interact directly with holographic images of network vulnerabilities or infrastructure maps projected on bezel-free screens. Early adopters are seeing 55% speed improvements for decision-making in multi-agency emergency exercises when fragmented monitoring systems are displaced by unified visual layers.

COB stands for Chip-On-Board, where LED chips are directly attached to the substrate, eliminating traditional wire bonding, enabling seamless integration for display technology.

MicroLED displays are self-emissive, featuring higher brightness levels (up to 5,000 nits) without burn-in risks, while Quantum Dot displays rely on a different technology with varying brightness levels.

Bezel-free walls eliminate visual barriers, improving situational awareness by providing seamless viewing of real-time data streams without stuttering gaps, enhancing response speed.

Predictive maintenance models monitor real-time operational conditions, predicting component wear and minimizing downtime by leveraging AI for extended display life beyond average limits.