Extreme changes in temperatures and moisture are a major concern for LED panels in public spaces. The daily heating and cooling cycles are detrimental to the tiny solder connections and printed circuitry. In temperatures above 60% relative humidity, there is a likelihood of condensation, which can lead to corrosion. With outdoor LEDs, consideration of thermal management systems is critical. If outdoor LEDs lack moisture control, short-circuited LEDs due to humidity can reduce the lifespan of the LEDs by 40% compared to LED displays in a controlled environment. This means outdoor screen displays require very high maintenance and replacement costs.

Dust, debris, and exposure in operations hubs and pedestrian zones

Displays in transit hubs like metro stations are constantly under attack from dust and exposure-related damage. The build-up of dust in these locations can be extreme: in some cases, exceeding 3 grams of dust per square meter weekly. Dust build-up obstructs air circulation, resulting in hot spots on equipment. Dust can also impede performance of technical parts of screens. The continuous vibration from rumbling trains, as well as the passing of patrons, impacts transit hubs and can cause significant damage. In extreme cases, the vibration can cause failures due to fatigue of the structural attachments holding screen modules. This is the reason why the use of impact resistant front covers, and IP65 rated boxes is critical not only to their operational performance, and visual clarity, but also to their ability to keep the internal components of the box and screen free from the dust and debris that can cause performance failure of the LEDs and screen.

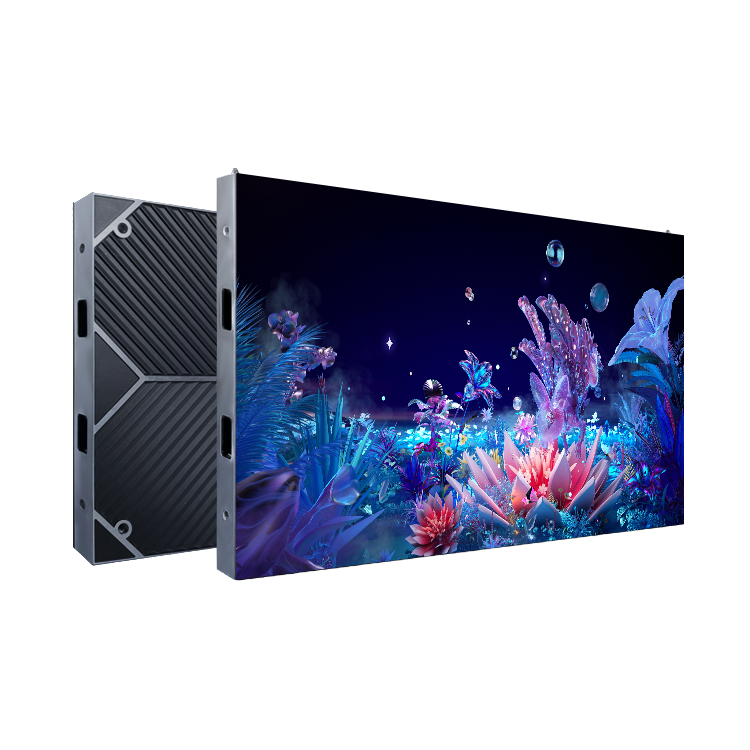

Skyworth LED Panel's IP Ratings, Structural Integrity, and Defense Against Vandalism

Skyworth LED Panel's IP65+ Protection and Outdoor Public Deployment Scenario Corrosion Resistance

Skyworth LED panels' IP65+ protection, waterproof, and dustproof protection allows protection from water jet dust ingress, irrespective of the direction of the water jet. This is especially significant for public display installations in areas where environmental conditions are unpredictable, such as train stations and outdoor events. Furthermore, the panel's enclosure is made from materials that are relatively resistant to corrosion. Aluminum corrosion is minimized through the use of coating, and gaskets that are beyond saline and industrial-grade corrosion. Outdoor displays that are unprotected along the coasts tend to fail twice as quickly as those within coastal protection. Coating corrosion is exceedingly evident, which is why manufacturers are encouraged to provide coastal protection.Impact Resistance and Stability of the Chassis Under Footfall and Transit Vibration

To withstand regular commercial specifications, the public displays need even higher durability. The Skyworth model is designed with an impact absorbing reinforced frame that withstands impact from accidental bumps and even subway vibrations at an average of 4.3 Hz which are quite extreme. These screens have driver boards designed for shock absorption, and 4mm tough tempered glass. They are designed to absorb forces up to 950 Newtons with ease and their mounts are designed to stop micro cracks from the solder joints from propagating. Switching to these displays, airport staff have reported a roughly 30% reduction in maintenance costs, which has been attributed to their increasing reliability, resulting in less “hands-on” maintenance.

Thermal Management and Component Quality: Validation of Outdoor LED Module Lifespan

Heat Management vs Urban Ambient Temperature Cycling

The lifespan of outdoor LED panels is greatly affected by the efficiency of the heat management system. It is well known that urban cities can experience extreme temperature variations, dropping to -40 degrees Celsius in the winter, and exceeding 50 degrees in the summer. Therefore, our heat management systems must be reliable in extreme conditions. While aluminum heat sinks are 40% better than plastic heat sinks in moving heat from LEDs, it is critical to keep LED junctions under 85 degrees Celsius. Above this threshold, temperature increases will result in drastic increases in LED module failure. It has been demonstrated that excellent thermal management can mitigate adverse weather conditions and cyclical thermal cycling. This is evidenced by the functionality of lights at transit stations that experience extreme weather and turn on and off at varying intervals.

Field-Based Degradation Analysis: Skyworth LED Panels in 24/7 Operation vs. L70 Claims

When manufacturing companies state 50,000-hour L70 lifespans, they are referring to laboratory testing. What about the lights that get installed 24/7 in airports and subways? We've noticed 15 - 20 percent quicker light output loss in the real world. Why? Heat and voltage variations are the two main reasons. To understand if the lights will last per the estimates, will require attempting to correlate the standard LM-80 reports with the temperature data taken directly at the light location. Some of the more sophisticated companies are well aware of the need to set the theoretical limits as a baseline for what is practical. For example, they are conducting infrared scans every three months to look at the “drivers” in order to identify and address developing hot spots.

Operational Longevity and Maintenance Efficiency of Skyworth LED Panels

Skyworth LED vehicles have been tested and validated to last over 50,000 hours, and still, do not have any brightness loss. These vehicles can even be used in extreme conditions and can be used 24 hours a day. These vehicles have a fully modular design. This allows technicians to perform repairs from the front without fully disassembling the entire vehicle. All components are modular and can be replaced quickly and easily. This has been shown to reduce repair time by about 70%. Each panel has a built-in smart thermal management system that also protects the components of the system from high temperatures, which can lead to costly repairs and replacements. These LED vehicles consume at least 85% less energy than traditional lighting vehicles, and also require much less maintenance. Skyworth LED vehicles have been shown to have failure rates of less than 0.5% in actual installations in public transport centers. These vehicles also have built-in remote monitoring that allows maintenance personnel to identify and address issues before they become larger problems.

Common Questions

What are some environmental challenges posed to public LED screens?

LED screens may face some challenges like extreme temperatures, humidity, dust, and impacts. All of these challenges may lead to reduced efficiency and or lifespan for the LED screen.

What does IP66 protection mean for LED screens?

LED Screens that are IP66 (and upwards) are protected from dust and outdoor water jets. Therefore, they can be used in public outdoor environments. This also prevents damage and corrosion from the outdoor environment.

What does thermal management mean for LED screens?

Thermal management = longer lifespan of LED Screens. The LED screens generate heat that needs to be dissipated to prolong the lifespan of the components by avoiding extreme temperature changes.

What is Skyworth doing around maintenance?

Skyworth LED screens are designed to have a modular design with standard components, therefore reducing time in repairs. This is also a result of thermal management and remote maintenance.

EN

EN

CH

CH FR

FR ES

ES AR

AR FA

FA AZ

AZ JA

JA KO

KO TL

TL ID

ID VI

VI TH

TH TR

TR BN

BN LO

LO MN

MN MY

MY KK

KK UZ

UZ KY

KY DE

DE IT

IT PT

PT RU

RU BG

BG HR

HR CS

CS DA

DA NL

NL PL

PL CA

CA SR

SR SQ

SQ HU

HU GA

GA CY

CY IS

IS EU

EU LA

LA